Polytron Lubricants, LLC

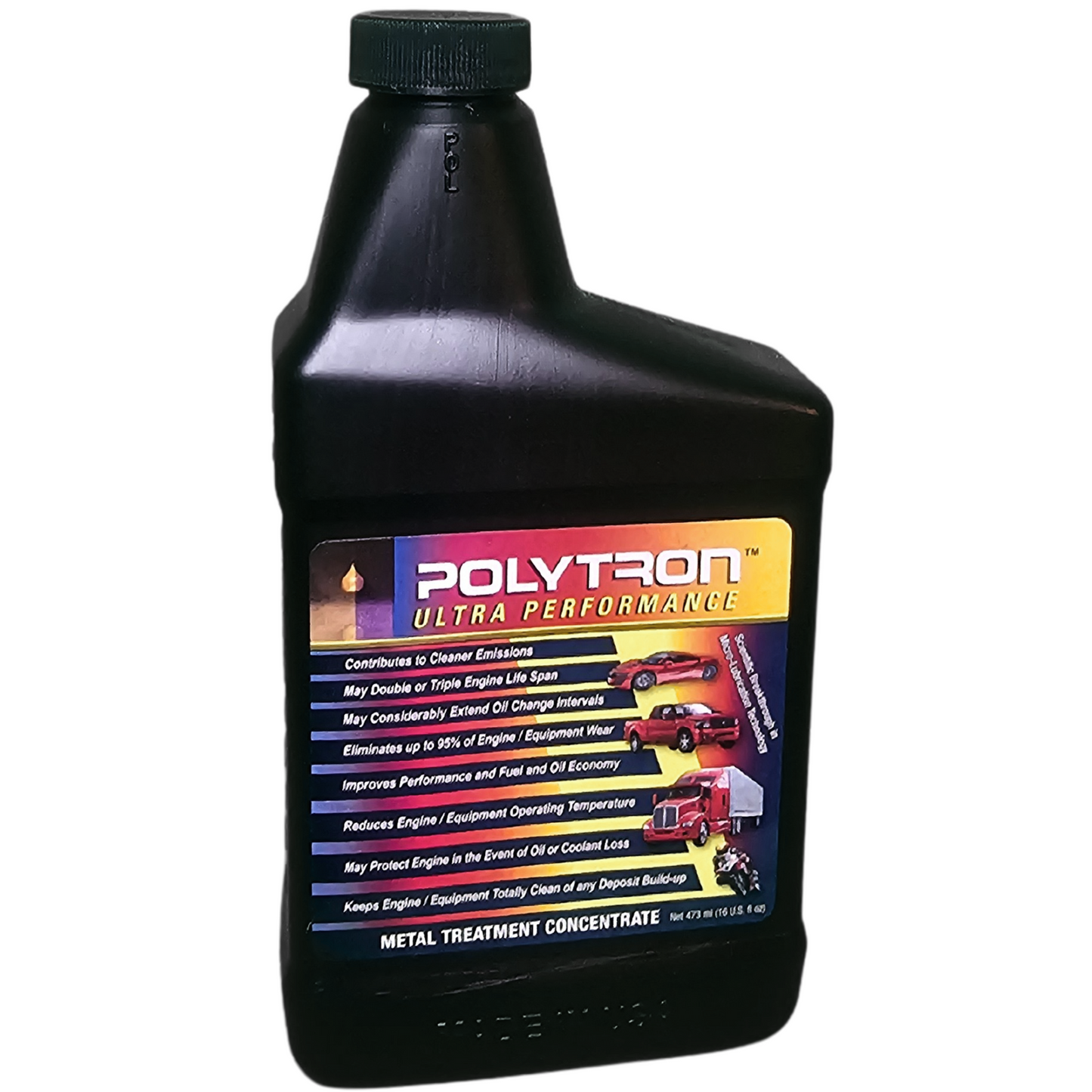

Polytron MTC (Metal Treatment Concentrate)

Polytron MTC (Metal Treatment Concentrate)

Couldn't load pickup availability

Polytron MTC employs a cutting-edge micro-metallurgical process to create a robust, polished micro-layer directly from the existing metal surface, remarkably enhancing resistance to wear, extreme pressure, and high temperatures. This enduring treatment ensures metal surfaces are constantly protected, offering immediate start-up lubrication. By significantly reducing friction and wear, Polytron MTC not only maximizes equipment lifespan and performance but also optimizes oil and fuel efficiency.

Discover the transformative power of Polytron MTC and ensure your equipment operates at its peak capability, day in and day out. Trust Polytron to deliver unparalleled protection and performance enhancement.

Polytron's advanced lubrication solutions are ideal for a wide array of industries, including automotive, industrial machinery, mining, construction, agricultural, marine, railroad, and fleet vehicles, ensuring unparalleled performance and efficiency across diverse applications.

How to Use Polytron MTC

How to Use Polytron MTC

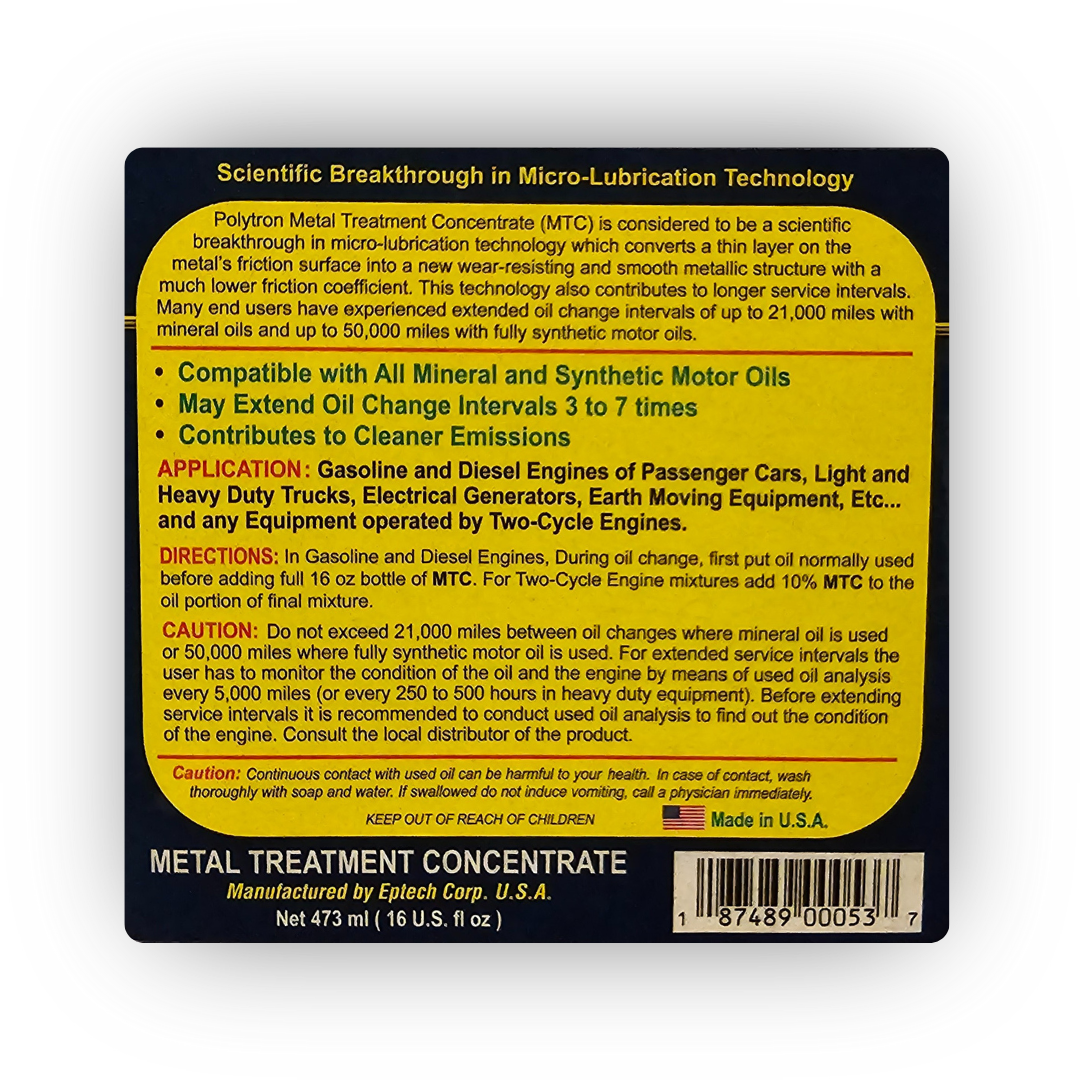

In Gasoline and Diesel Engines, during oil change, first put oil normally used before adding full 16 oz bottle of MTC. For two-cycle engine mixture add 5% MTC to the oil portion of final mixture.

- If used for the first time, apply it at least 200 miles before the next oil change, and then apply it again in the next oil change.

- If oil change intervals are as per the car manufacturer’s instructions, apply Polytron MTC every other oil change.

- In extended oil change intervals, (20,000 to 50,000 miles) add 10% Polytron MTC every oil change.

Please perform a Used Oil Analysis to determine the feasibility of your engine before continuing with extended oil change intervals.

- Motor Oil: add 10%

- Automatic Transmission Fluid: add 5%

- Manual Transmission Fluid: add 10%

- Hydraulic Systems: add 5%

- Gear Boxes: add 5%

- Bearing Journals: add 5%

Note: All are in % by volume.

Unparalleled Protection and Performance Enhancement for Your Equipment

Unparalleled Protection and Performance Enhancement for Your Equipment

Polytron MTC is considered to be a scientific breakthrough in micro-lubrication technology which converts a thin layer on the metal's friction surface into a new wear-resistant and smooth metallic structure with a much lower friction coefficient. This technology also contributes to longer service intervals. Many end users have experienced extended oil change intervals of up to 21,000 miles with mineral oils and up to 50,000 miles with fully synthetic motor oils.

Key Benefits

Key Benefits

- Drastic Wear Resistance: Experience an up to 95% decrease in wear, substantially extending the life and reliability of your equipment.

- Withstands Extreme Conditions: Polytron MTC's unique formula makes it exceptionally resilient against extreme pressure and high temperatures, safeguarding your machinery in the most challenging environments.

- Boosts Efficiency and Power: Notice a significant enhancement in both the efficiency and power of your equipment, optimizing performance like never before.

- Emergency Protection: In the rare event of an oil or coolant loss, Polytron MTC acts as a temporary guardian, protecting your engine from catastrophic damages and giving you precious time to address the issue.

- Easy to Use: Simply integrate Polytron MTC into your regular maintenance routine by adding it at a 5% volume ratio to your main lubricant. It's that easy to give your machinery the Polytron advantage!

Share

Revolutionize your engine's performance.

How Does MTC Work?

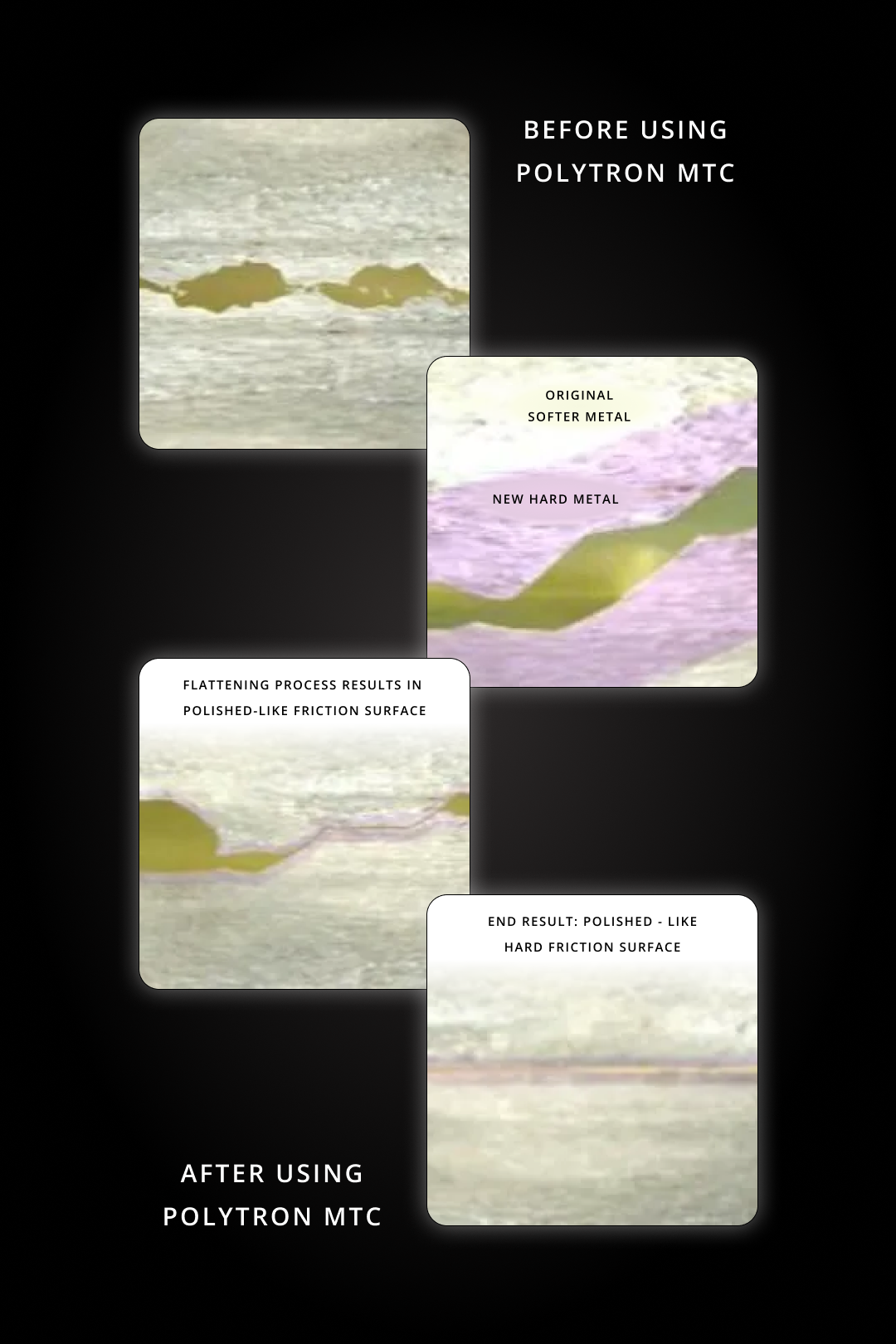

Because active elements of Polytron are polarized, when Polytron MTC is applied, they are attracted to the metal. Under heat and pressure these polarized elements metallurgically impregnate the metal’s crystal structure on its mating friction surfaces.

Polytron MTC transforms metal surfaces through a unique metallurgical process, creating a thin, hard layer that extends the metal's wear life by at least 15 times compared to its original state. This new layer, while extremely hard, is also flexible, allowing it to absorb and redistribute force without breaking, leading to a significant reduction in wear and tear. The process effectively smooths out the metal surface, reducing friction and making it more durable and efficient. This dual benefit of increased hardness and smoothness not only dramatically reduces wear but also lowers friction, enhancing the overall performance and longevity of the metal.

Experience the Power of Polytron Today!

Featured collection

-

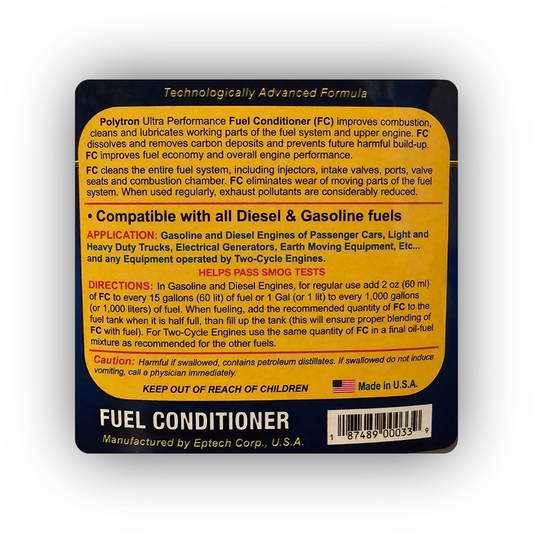

Polytron GDFC (Gasoline/Diesel Fuel Conditioner)

Regular price $23.95Regular priceUnit price / per -

PENETRATING LUBRICANT

Regular price $23.95Regular priceUnit price / per -

Polytron EP-2 Lithium Complex Grease

Regular price $23.95Regular priceUnit price / per