Mining

Enhancing Mining Operations with Polytron:

In the demanding and harsh conditions of mining, Polytron Lubrication Technology stands out for its ability to substantially reduce operating costs by up to 50% and cut downtime for maintenance and repairs by a similar margin.

Robust Solutions for Harsh Mining Environments:

Challenges in Mining Operations: Operating mining equipment in environments characterized by dust, mud, moisture, extreme temperatures, and high loads is incredibly challenging. Polytron Lubrication Technology is designed to meet these challenges head-on, ensuring reliable and efficient operation of mining machinery.

Significant Reduction in Operating Costs: By adopting Polytron technology, mining operations can achieve a reduction in operating costs by up to 50%. This is a crucial factor in an industry where cost efficiency is directly linked to profitability.

Dramatically Lower Downtime: Maintenance and repair are constant concerns in mining due to the intense wear and tear on equipment. Polytron helps reduce downtime for the maintenance and repairs of essential equipment like generators, compressors, excavators, bulldozers, dump trucks, pumps, graders, and conveyors by up to 50%, thus minimizing operational disruptions.

Boosted Productivity: With Polytron, productivity in mining operations can increase substantially. This is because the technology ensures that machinery operates smoothly and reliably, even under the most strenuous conditions.

Extended Equipment Service Life: One of the most significant benefits of Polytron in the mining industry is the extension of the service life of equipment by up to 600%. This not only means less frequent replacements but also translates into long-term cost savings and sustainability.

Fuel and Oil Consumption Savings: Efficient lubrication leads to reduced fuel and oil consumption, which is another way Polytron contributes to the cost-effectiveness and environmental sustainability of mining operations.

Frequently Asked Questions

How do Polytron products improve machinery performance?

Polytron products are engineered to significantly enhance machinery performance through their advanced lubrication technology. By reducing friction and wear between moving parts, they allow engines and equipment to operate more smoothly and efficiently. This reduction in friction not only leads to a decrease in energy consumption but also minimizes heat generation and mechanical stress, extending the lifespan of machinery components. As a result, users can expect improved operational reliability, reduced maintenance costs, and in some cases, enhanced fuel efficiency. Essentially, Polytron's formulations work at the molecular level to form a durable lubricating layer, ensuring optimal performance even under extreme conditions.

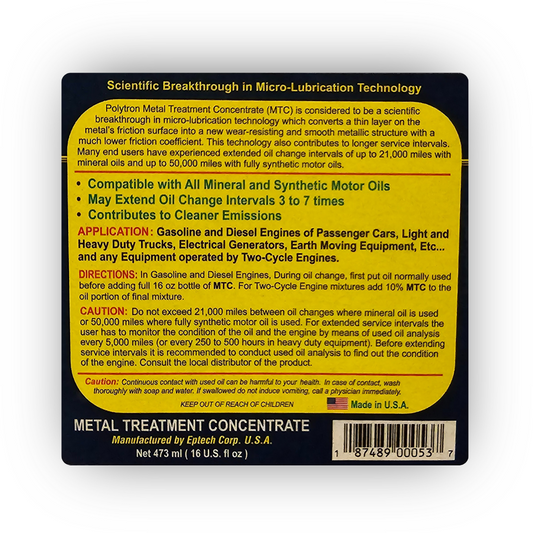

Can Polytron MTC be used with any type of engine oil?

Polytron MTC is designed to be universally compatible with all types of engine oils, whether they are synthetic, semi-synthetic, or mineral-based. Its unique formulation enhances the existing oil's properties, providing superior protection and performance without altering the chemical structure of the base oil. This compatibility ensures that Polytron MTC can be safely added to any engine, enhancing lubrication, reducing wear, and improving overall engine efficiency regardless of the original oil type used.

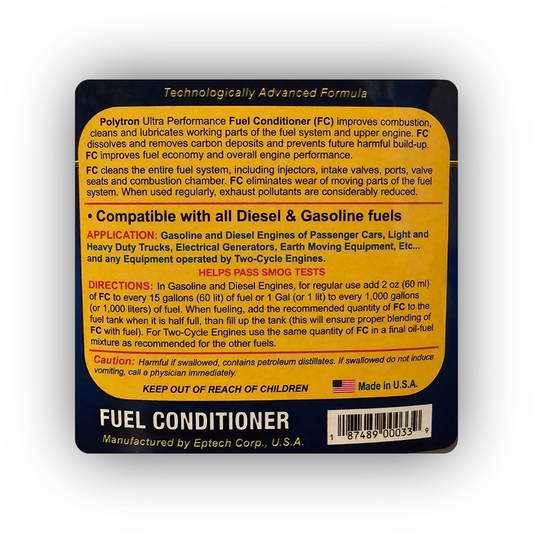

What makes Polytron Fuel Conditioner different from other fuel additives?

Polytron Fuel Conditioner stands out from other fuel additives due to its unique formulation that enhances fuel quality and efficiency. It is designed to optimize combustion, reduce harmful emissions, and improve overall engine performance. Unlike typical additives, Polytron Fuel Conditioner works at the molecular level, ensuring a cleaner and more complete fuel burn. This leads to improved fuel economy, reduced engine wear, and extended maintenance intervals, making it a superior choice for maintaining and enhancing the performance of various engines.

How often should I apply Polytron MTC?

Polytron Metal Treatment Concentrate (MTC) should be applied according to the specific requirements of your machinery and the operating conditions it is subjected to. Generally, it's recommended to add Polytron MTC during oil changes, mixing it with your engine or gear oil at a ratio of 10% for initial treatment and 5% for subsequent applications. However, for the best results and to tailor the application to your equipment's needs, it's advisable to consult the user manual or contact Polytron directly for more detailed guidance. This ensures optimal performance and longevity of your machinery.

Is Polytron PL suitable for all metal surfaces?

Polytron Penetrating Lubricant (PL) is designed to be versatile and effective on a wide range of metal surfaces. Its advanced formula penetrates deeply into metal pores, providing superior lubrication, reducing friction, and protecting against rust and corrosion. While it is suitable for most metal types, it's always best to check the compatibility with specific materials or under extreme conditions. For specialized applications or unusual metals, consulting the product documentation or reaching out to our technical support can provide additional guidance to ensure optimal performance and safety.

Can Polytron products be used in both old and new machinery?

Polytron products are designed with advanced technology that makes them suitable for use in both old and new machinery. They are engineered to enhance the performance and extend the life of mechanical components by reducing friction, wear, and tear. For older machinery, Polytron can help revitalize and maintain efficient operation, potentially reducing the need for frequent repairs. In new machinery, it aids in maintaining optimal performance levels from the start, ensuring that the equipment runs smoothly and efficiently. This versatility makes Polytron products an excellent choice for a wide range of applications, ensuring reliability and longevity regardless of the machinery's age.

How does Polytron contribute to fuel and oil economy?

Polytron products are designed to enhance the efficiency and longevity of machinery by reducing friction and wear, leading to significant fuel and oil savings. By forming a micro-layer of protection on metal surfaces, they decrease mechanical resistance, allowing engines and machinery to operate more smoothly and efficiently. This reduction in friction not only extends the life of the oil by decreasing its degradation rate but also optimizes fuel consumption. Consequently, users experience improved performance, reduced maintenance costs, and lower environmental impact through decreased emissions and resource use.

Are there any environmental benefits to using Polytron products?

Polytron products are designed with environmental benefits in mind. By enhancing the efficiency and longevity of machinery, these products contribute to reduced energy consumption and lower emissions. This efficiency boost means engines and machinery operate more cleanly and with less waste, aligning with eco-friendly practices. Additionally, the extended lifespan of lubricated parts decreases the need for frequent replacements, thus reducing waste and conserving resources. By optimizing performance and minimizing environmental impact, Polytron supports sustainable practices in various industries.

How does Polytron ensure the longevity of machinery parts?

Polytron products are engineered to significantly extend the life of machinery parts. They achieve this by forming a micro-layer of protective film on metal surfaces, reducing friction and wear even under extreme conditions. This protective layer helps in preventing metal-to-metal contact, which is a common cause of premature wear and tear. As a result, machinery experiences less mechanical stress, leading to enhanced durability and a longer operational lifespan. This proactive approach to maintenance ensures that parts remain in optimal condition for extended periods, reducing the need for frequent replacements and repairs

Where can I purchase Polytron products for personal or business use?

Polytron products are available for purchase through our official website, authorized distributors, and select retail outlets. For personal use, you can easily order online with options for direct shipping to your location. For business or industrial applications, we recommend contacting our sales team via the website's contact form or directly reaching out to our authorized distributors. This ensures you receive tailored advice and the most suitable product options for your specific needs. For larger orders or specialized requirements, our sales team can provide customized solutions and bulk pricing options.

Featured collection

-

Polytron MTC (Metal Treatment Concentrate)

Regular price $31.19Regular priceUnit price / per -

Polytron GDFC (Gasoline/Diesel Fuel Conditioner)

Regular price $23.95Regular priceUnit price / per -

PENETRATING LUBRICANT

Regular price $23.95Regular priceUnit price / per -

Polytron EP-2 Lithium Complex Grease

Regular price $23.95Regular priceUnit price / per